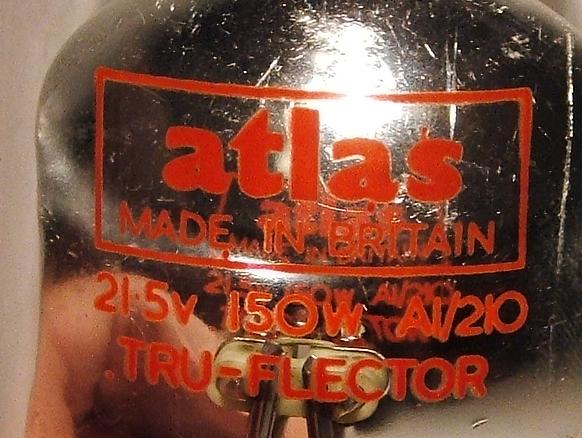

| Manufacturer: | Atlas Lighting Limited |

| Model: | A1/210 21.5V 150W "Tru-flector" |

| Application: | Slide Projection |

| Wattage: | 150W |

| Diameter (max): | 38mm (1 1/2") |

| Length: | 88mm |

| Tube Length: | N/A |

| Bulb/Tube material: | Clear Quartz |

| Colour Temperature: | Unknown |

| Peak output wavelength: | Broadband Emission |

| Total light output: | Unknown |

| Rated lifetime: | Unknown |

| Cap: | 4-pin Octal Valve Base |

| Operating voltage: | 21.5V |

| Operating current: | 9.98A (Calculated) |

| Warmup/restrike time: | None |

| Cost (original): | Unknown |

| Value (now): | Unknown |

| Place of manufacture: | Great Britain |

| Date of manufacture: | Unknown - Date code 5F on lamp (June 1975?) |

| Lamp Status: | Apparently new, untested |

I think this is the first projector lamp I've actually catalogued in my collection - though I know that there are another couple in there. Though I'm meaning slide projector here, as I know there's one in this section from an overhead transparency projector as well.

Very early film projectors used carbon rods to produce their light, which while very bright required continual attention, made a horrendous amount of noise, used even more horrendous amounts of power, and produced enough UV to cook anyone nearby who wasn't protected against it. Needless to say, when filament lamps capable of filling the same role, then followed by discharge lamps, these were innovations very quickly picked up. It's only since 2004 or so that relatively affordable (LCD) projectors have started to appear in the home, using ultra-high-pressure mercury discharge lamps to produce their light. Before that, the lamp in a home based projector would almost exclusively have been incandescent.

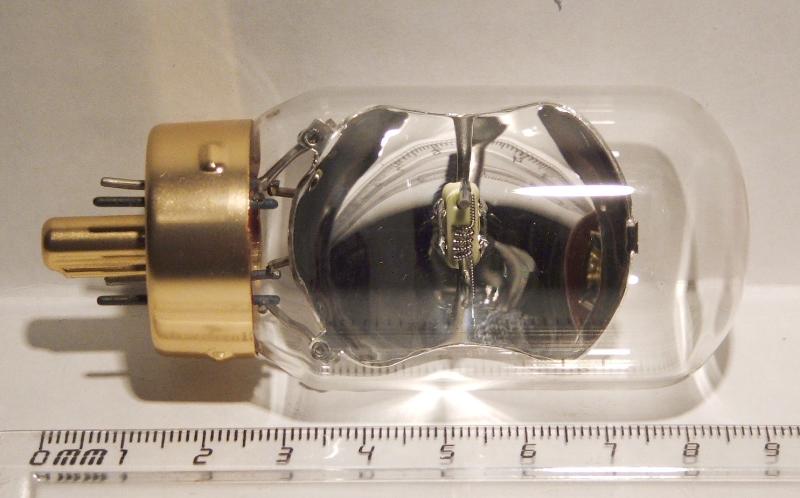

You couldn't just pick a high wattage incandescent up and stuff it in front of a mirror though. Projectors need a very precisely focused light source to "inject" the light correctly into their optical system, otherwise you'll end up with one part of the image brighter than another, or just no light at all being apparent on the screen. Higher wattage lamps (generally for movie projectors) tended to use lamps with a carefully designed filament with a very tightly packed zigzag shape to present a square uniform area of light. Smaller lamps used a bit more varied methods though, such as this lamp which uses a very small filament for the wattage and a specially designed, highly reflective reflector to deliver a precisely focused beam of light into the projectors optical system. Of course, having the reflector built into the lamp means that a nice new, clean one is installed with each new lamp. Especially important in an application such as this where one stray fingerprint could be a real problem. The key in the base on this lamp would align with one in the socket for the lamp, meaning that it will always slot in in the correct position for operation.

This is a lovely made piece of lighting technology. Everything about it is very precise, and the reflector is very, very highly polished indeed.

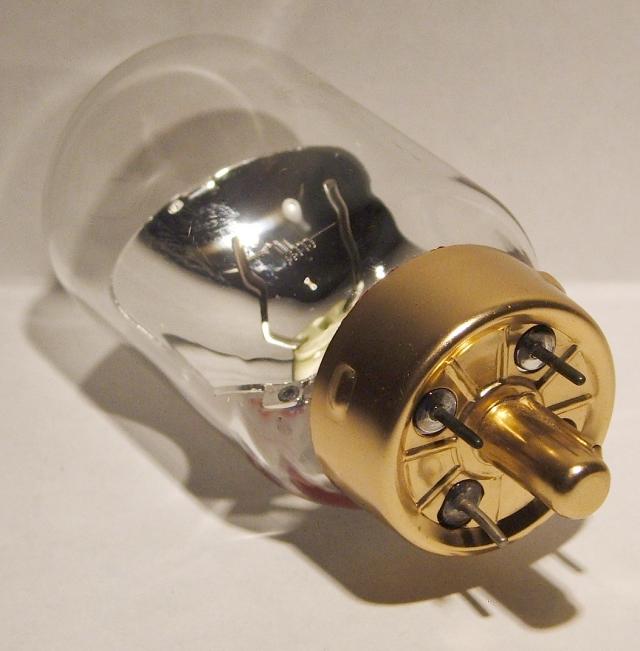

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - General overview of lamp

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Detail of lamp cap

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Overview of lamp packaging

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Detail of internal reflector

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Held in hand for scale

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Detail of lamp from side showing reflector profile

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Displayed with ruler to show size of lamp

Atlas A1/210 21.5V 150W Tru-flector Projector Lamp - Detail of text printed on lamp

This lamp added to the Virtual Display Shelf on the 21st September 2007 at 01:15.

References: None.

Acknowledgements: Many thanks to the website reader who donated this lamp (amongst many, many others) for display.

This page last updated:

16th June 2023: Made changes to page formatting to improve readability on mobile devices and some background code changes to improve search engine behaviour.