| Manufacturer: | Philips |

| Model: | Master QL 85W/830 |

| Application: | General Lighting - Industrial, extreme lifetime applications eg sealed-for-life explosion-proof units |

| Wattage: | 85W |

| Width (max): | Lamp only: 100mm |

| Length: | Lamp only: 170mm |

| Tube Length: | N/A |

| Bulb/Tube material: | Glass, colour 830 phosphor on inner surface |

| Colour Temperature: | 3000K - Bright White |

| Peak output wavelength: | N/A |

| Total light output: | 6000Lm (Manufacturer's claim - 70.6Lm/W) |

| Rated lifetime: | 100,000 hours |

| Cap: | Custom Twist-lock plastic cap |

| Operating voltage: | (Driver): 200-277V AC/DC 50/60Hz |

| Operating current: | 300-400mA |

| Warmup/restrike time: | 1 minute/none |

| Cost (original): | Unknown |

| Value (now): | $316.66 (Aug 2007) |

| Place of manufacture: | Lamp: Holland. Driver: Poland. |

| Date of manufacture: | Circa 2005. Date code D05 on lamp, and G05 on driver. This appears to be a new format of code for Philips. |

| Lamp Status: | Working |

| Related Pages: | None |

Given the rarity of these lamps, I was hugely surprised to come to own one! Given that it was so kindly donated to me, I feel somewhat guilty that it's taken me so long to finish its page.

The Philips QL Electrodeless Induction Lighting System first saw the light of day in 1991 - coinciding with the 100th anniversary of the company. Quite an achievement for Philips, having the first commercially available induction lighting system. Despite a huge price tag, this system had a lot to offer. Not least the 100K hour life expectancy - a figure greater than anything ever seen before aside from the clipboards of designers of other lighting companies busily working away at their own induction systems. The magic 100K mark can in theory be reached by white LEDs now - but only in the last year or so have they really started to appear with sufficient luminous flux and suitable colour rendering ability to serve a useful purpose for general lighting. This however was 1991 - white LEDs were yet to be invented - and were a good ten years away from being an everyday item. Nothing could provide a lifetime like that, never mind with efficacy figures like 70Lm/W. Colour rendering was basically on a par with the best fluorescents of the day - with all the familiar colours appearing. The example here is 830, though I have also heard of 840 coloured lamps in existence.

Obviously, with the units costing the same as a cheap second hand car, these were not really aimed at the general public - they were aimed at industry, where the huge reduction in maintenance costs possible due to the huge lifetime of the unit could really be capitalised upon. Incidentally, the clock faces of the iconic Big Ben clocktower in London are lit by Philips QL lamps at night (Until the late 1990s, this work was performed by blended mercury lamps).

One area of industry where the QL lamp has turned out to be really rather well suited to is the oil & gas industry. Lighting on an oil/gas platform is somewhat more complex than most other places due to regulations in place there relating to the possible presence of explosive gases. A sensible precaution I might add! This leads to regulations such as luminaries requiring to be totally sealed, fluorescent lamps not being allowed to be preheated, and other regulations relating to maximum permissible surface temperatures all apply. I've never worked on a drilling platform - but I'm sure the list is as long as my arm. What the QL has made possible though, is the construction of an all-in-one, sealed for life, Zone 1 rated unit. Ready to bolt in place, wire up and switch on. The totally sealed unit should have a lifetime of around ten years (obviously, the outer casing has to be built to stand up to the elements or its operating environment for this amount of time too!). IMT Lighting (Who get a free plug here, because they gave me stuff!) are one such company specialising in construction of such luminaries.

The characteristics of the QL lamp mean that early failures (such as those which plagued low pressure sodium lamps for many years) should really be non-existent. There is really very little to go wrong with the lamps themselves - the 100K figure quoted by Philips actually being determined by the driver rather than the lamp itself. Obviously though, a drop in luminous output will occur over time as the phosphor ages. The 50% mark being hit at around 120-150K hours - obviously the driver and lamp were really intended to be sold and replaced as one unit as far as Philips were concerned.

What does this thing actually consist of then?

Quite simply, the lamp, the driver, and the antenna.

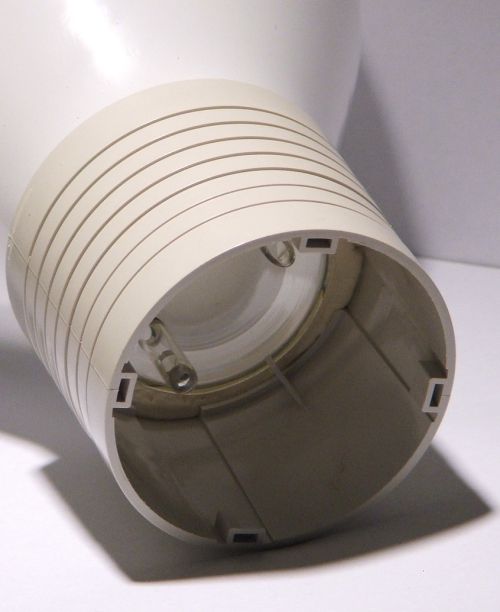

The lamp is simply a soft glass bulb with an argon-neon atmosphere in side it, and a mercury amalgam (two actually - one in a tip-off near the base, and one on the antenna re-entrant portion), and a phosphor/anti blackening coating on the inner wall. This re-entrant is shaped so that the antenna fits correctly inside it, and is coated with an emissive coating. The outer surface of the bulb is coated with a thin conductive layer to act as an RF shield. Picking up the lamp itself, it feels oddly light due to the lack of hardware inside it. The special cap is made of plastic as well, adding to the complete absence of weight!

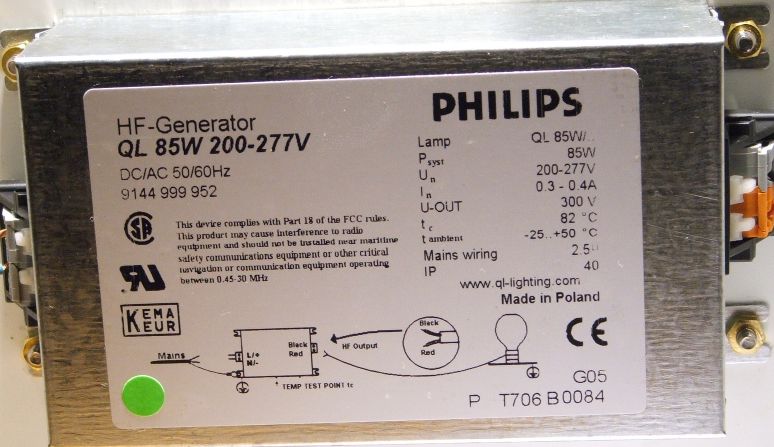

The driver is a little silver box which is mounted near to the lamp, looking just like the ballast for any commercial metal halide installation really. This is connected to the mains, and provides the power to the lamp, driving the antenna at 2.65MHz. This frequency was carefully chosen to minimise the potential for the system to interfere with other equipment (a problem encountered extensively during the development of this technology by both Philips and other manufacturers), yet provide good coupling efficiency.

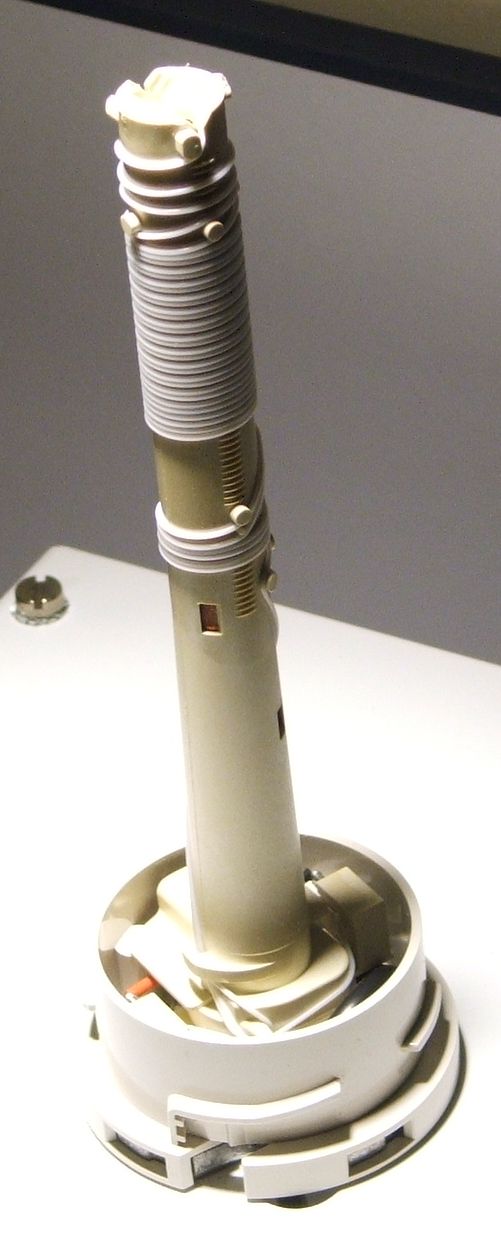

The antenna itself is just what it looks like - a short coil of insulated wire, which is positioned inside the re-entrant part of the bulb during operation. The antenna is built around a heat-pipe, which must be securely clamped to a thermally conductive base - as this can have a significant effect on the efficacy of the lamp during operation. In the case of my lamp, after it has been running for 30 minutes or so, the whole upper "deck" that the antenna is clamped to becomes warm.

Philips Master QL 85W/830 Induction Lamp - General overview

Philips Master QL 85W/830 Induction Lamp - Detail of the antenna used to couple energy into the discharge vessel

Philips Master QL 85W/830 Induction Lamp - Detail of the lamp cap

Philips Master QL 85W/830 Induction Lamp - Detail of complete assembly - Ballast unit is bolted to underside of lower level

Philips Master QL 85W/830 Induction Lamp - Detail of HF Driver Unit

Philips Master QL 85W/830 Induction Lamp - Size of lamp shown

Philips Master QL 85W/830 Induction Lamp - Detail of text printed on lamp crown

Philips Master QL 85W/830 Induction Lamp - The very sturdy box I really wasn't expecting to be sent by IMT Bv, I'm still eternally grateful for them donating this to me!

This Lamp added to the Virtual Display Shelf at: 23:09 on September 28th 2005.

References: Lamp packaging and markings only.

Acknowledgements:

MANY THANKS TO JAN GELUCK OF IMT LIGHTING FOR DONATING THIS LAMP AND FIXTURE!

This page last updated:

19th June 2023: Made changes to page formatting to improve readability on mobile devices. Also made some background code changes to improve search engine behaviour.